Supply of the burner and postcombustor automation

DVD Tecno S.r.l. engineered and supplied the burner, the gas ramp and the instrumentation of a post-combustor for the biomass syngas power production plant. The plant is capable of producing 11MWe from 55 ton/yr. of biomass (mainly wood and prunings) and non-dangerous industrial waste (mainly paper, tissues, and wood, which previously ended in a landfill).

Contact UsProject Details

- Start: February 2016

- End: December 2012

- Place: Morcenx, France

- Amount: 900,000 €

- Client: ITT S.p.A.

- End Client: CHO Power (Europlasma)

- Type:

- Client Website

In the scope of a project, financed by the European Union, for the construction of a biomass syngas power production plant, our Client was the responsible for the design and supply of the combustor for steam production. DVD Tecno S.r.l. was put in charge of the engineering and supply of the burner together with its automation system.

The project

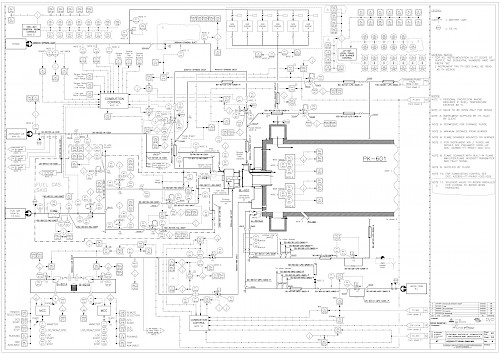

The project concerned the development of the new combustion management system, including the single two-stages burner (about 32 Gcal/h), the gas ramps, the safety and control system, and the connected supervision station.

The installation

DVD Tecno S.r.l. supervised the installation of the supplied parts during the plant construction, following with the commissioning of the new system.

The start-up

Once the assembly, the tests and the approval by the official bodies was completed, DVD Tecno S.r.l. followed also the start-up of the combustor and the tuning of the post-combustion section of the plant.

The energy and environmental savings

At steady-state, the plant produces enough renewable electrical power to meet the energy requirements of about 45.000 people.