Steam production boiler revamping

DVD Tecno S.r.l. took care of the revamping of the steam production boilers for the Ammonia III and IV plants owned by Azomures (Romania).

Contact UsProject Details

- Start: June 2015

- End: June 2016

- Place: Tirgu Mures, Romania

- Amount: 1,800,000 €

- Client: S.C.Azomures S.A.

- Contract: EPC

- Type:

- Client Website

In the scope of a bigger optimization project for the two twin plants for the production of ammonia (Ammonia III and Ammonia IV), the Client intrusted DVD Tecno S.r.l. with the update and optimization of the combustion system of the auxiliary boilers for steam production connected to those plants.

The project

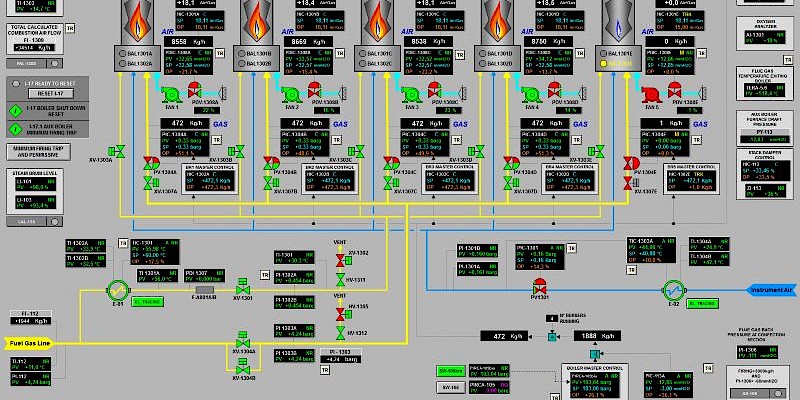

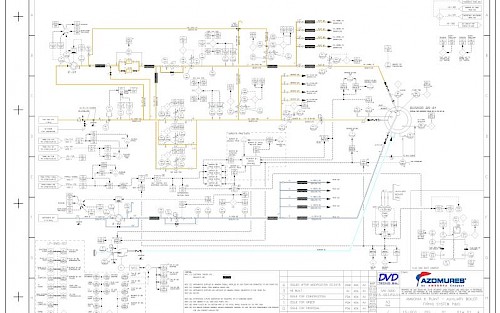

The scope of the project comprehended the complete new combustion management system for the auxiliary boilers, including a set of new burners (five for each plant with a power of about 15.000.000kcal/h each, substituting the pre-existing ones), the connected gas ramps, the dampers for the air partialization to the burners and flue gas, and the control and safety system, together with a supervision and control station.

The installation

During the programmed plant stops (September/October 2015 for Ammonia III and March/April 2016 for Ammonia IV), we dismantled the old burners and gas pipes, and installed the new components we designed and supplied. In the same time frame we also proceeded to the complete commissioning of the new system.

The start-up

Once the assembly and testing was completed, and the approval from the competent bodies received, we proceeded to the programmed restart of the boilers (December 2015 for Ammonia III and June 2016 for Ammonia IV) and to the tuning of the new systems, finally delivering the new working plant to the Client.

The energy and environmental savings

Based on the previous expenditure data provided by the Client, DVD Tecno S.r.l. extimated that, for each boiler, the revamping allowed:

- a saving of about 350Nm3/h of natural gas, thanks to the improved efficiency of the burners and to the optimization and automation of the combustion process;

- a reduction of about 100kVA of the required steady-state electrical power needed by the combustion air fans, mainly due to the installation of the dampers on their inlet instead of what was foresee in the original design (air partialization on the fan outlet). The Client chose not to use inverters on the electrical motors.